Photo: Heller-Leder - Archiv

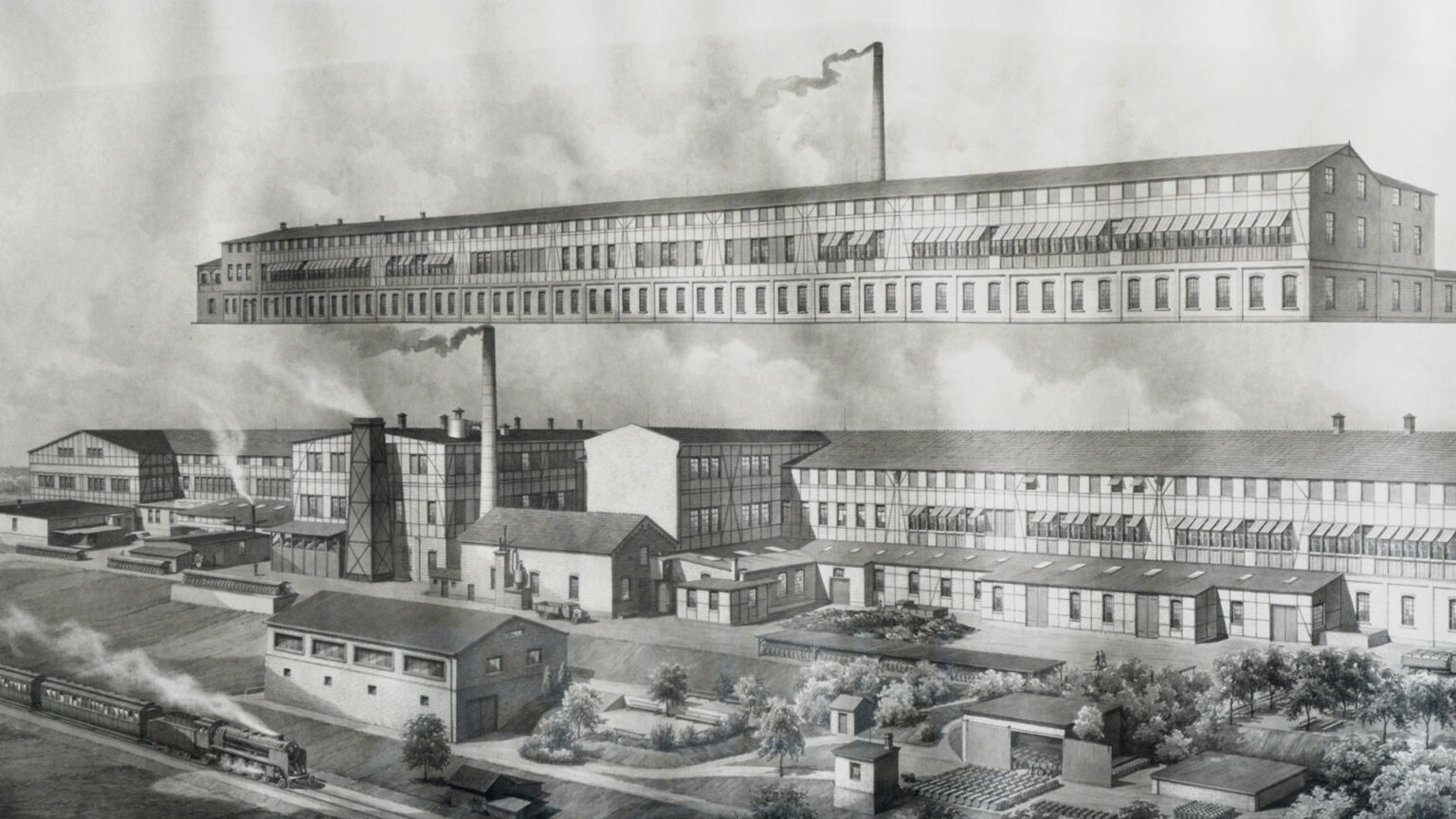

1919/20

Foundation of “BRAUNSCHWEIGISCHE LEDERWERKE HELLER & CAHEN.” This name was chosen at the time because Hehlen belonged to the Free State of Brunswick. Weekly production amounted to approximately 500 hides for the furniture and chair seat industry. Tanning was carried out in tanning pits, as was customary at the time.

Photo: Heller-Leder - Archiv

1936

Renamed “BRAUNSCHWEIGISCHE LEDERWERKE J.u.E. HELLER.”

Photo: Heller-Leder - Archiv

1954

The factory building in the 1950s.

Photo: Heller-Leder - Archiv

Extensive building extensions and increases in production.

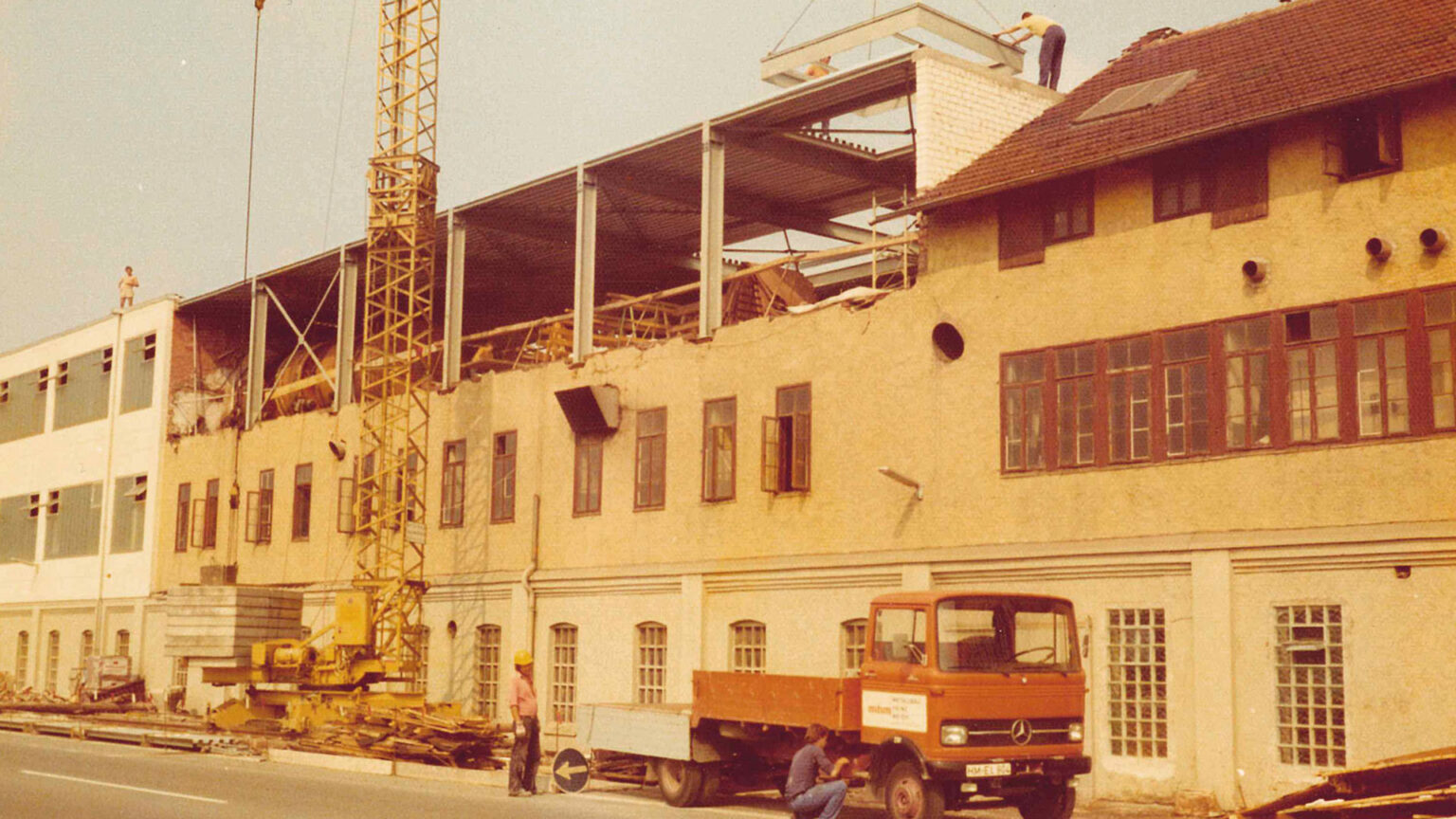

1972 - 1976

In the 1970s, the entire attic was converted. This changed the familiar appearance of the building, as the series of photos clearly shows. The extension of the building created plenty of space for new, modern machinery and equipment.

Photo: Heller-Leder - Archiv

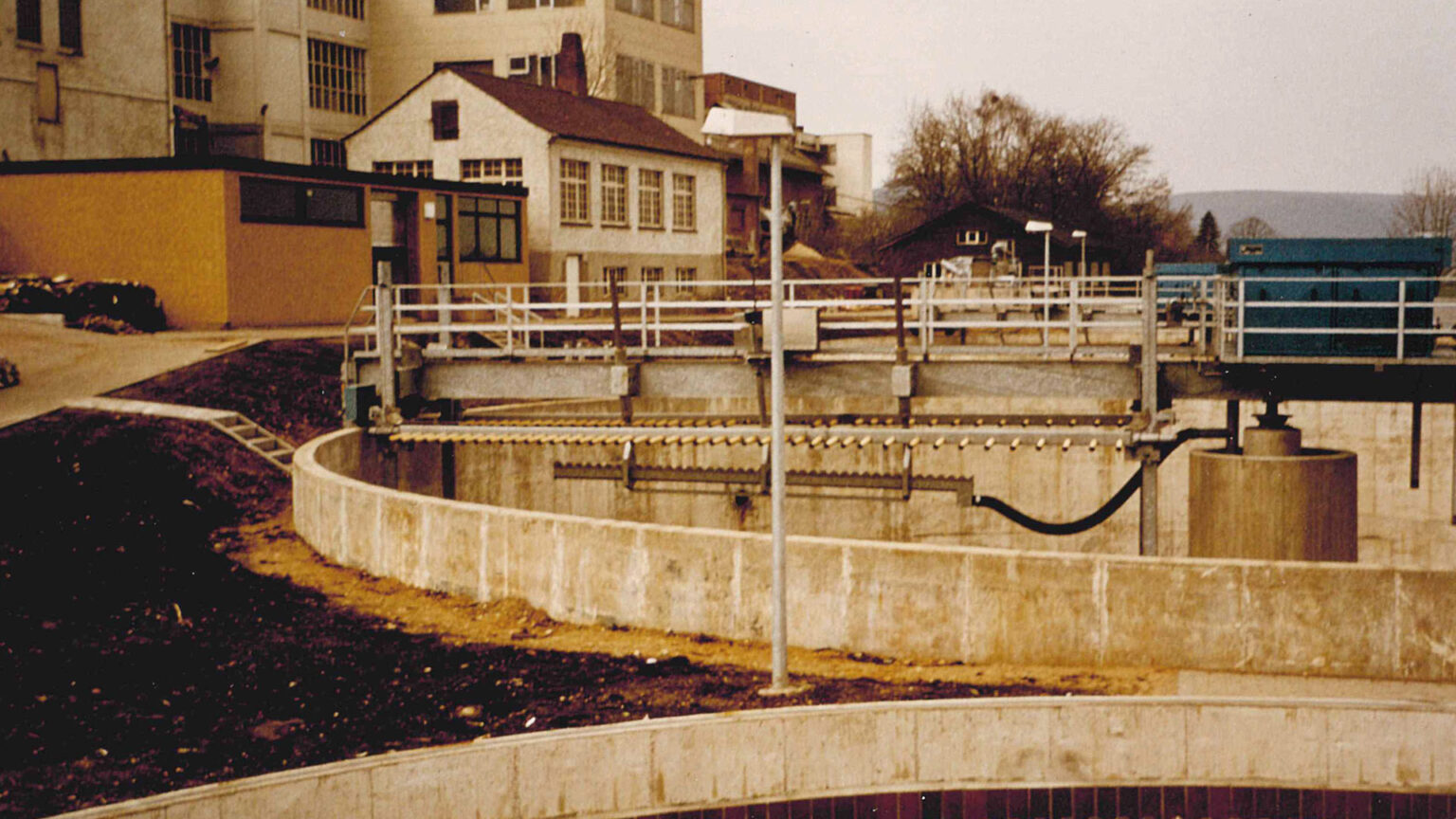

Construction of the company's own fully biological wastewater treatment plant with environmental laboratory

1983

Nach intensiver Planung erfolgt die Umsetzung des Baus der vollbiologischen Kläranlage. Somit wurde ein wichtiger Grundstein für die Zukunft des Unternehmens gesetzt. Ohne diese Kläranlage wäre eine vollstufige Produktion von Leder in Deutschland nicht möglich.

Photo: Heller-Leder - Archiv

New construction of the water workshop

1984 - 1985

The new hall was built to accommodate the increased production volumes at the time and to enable further increases in production in the future.

Photo: Heller-Leder - Archiv

Thomas Strebost takes over management of the company in its fourth generation

1991

Following the untimely death of Hans-Wilhelm Strebost, Thomas Strebost takes over the company. At his side is Rudolf Ebeling, a long-time companion and friend of the family.

Photo: Heller-Leder - Archiv

New construction of materials testing laboratory and expansion of environmental laboratory.

1999

Due to increasing quality and environmental requirements from customers and authorities, investments are made in materials testing and the environmental laboratory. In addition, a quality management system in accordance with DIN EN ISO 9001, QS 9000, and VDA 6.1 is introduced.

Photo: Heller-Leder - Archiv

New dyeing plant built and drying facilities modernized

2000

To counteract the lack of space at the main site and enable production to be expanded, 12 million German marks were invested.

Photo: Heller-Leder - Archiv

The best tannery in the world

2011

HELLER-LEDER is named “TANNERY OF THE YEAR” in Shanghai. The award takes into account factors such as environmental protection, social responsibility, research projects, technologies, and innovation, as well as the company’s influence on the global market.